ComSubFor Must Have A "Six Sigma Black Belt" On Staff

Over at the SubLant web page, I found a description of the "Undersea Enterprise" initiative (Adobe Acrobat document). Here's only one of the exciting highlights of what I'm sure will make us an Industry Leader in undersea warfare:

"Structure: CSF’s effects based management structure consists of a USE Flag Panel, and supporting policy and action teams. CSF leverages the USE Flag Panel, as supported by cross-functional teams (CFT), to increase the productivity of delivering warfare capacity to meet operational demand. The USE Flag Panel, by setting strategy and approving and monitoring metrics linked to personal accountability, uses CFTs to provide the integration of enterprise activities to meet USE objectives."

Doesn't that sound like it's straight out of Dilbert? Maybe one of the active duty guys who read this can enlighten me, but it looks at first glance to be one of those complete wastes of time that will quietly fade away whenever we have the next change at the top of CSF.

Maybe I'm being a little bit cynical. After all, they do have Measures Of Performance:

"• Operational Availability – “Around the World; Around the Clock” - Submarines and undersea surveillance assets deployed for sustained battle space preparation and deterrence

• Improved Commanding Officer Decision-Making – CO’s making optimal decisions under the demands and complexity of the undersea environment

• Submarine Expertise - Experienced people integrated throughout the Joint war fighting, military technology and defense/government management communities

• Culture/Standards/Conduct – “Pride Runs Deep” – Assimilating new crew members into the submarine culture, while maintaining high standards and conduct

• Future Capabilities – Forecasting and meeting tomorrow’s requirements for undersea superiority"

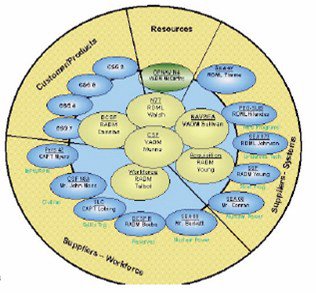

Plus, they have some sort of Venn diagram!

I was wrong... this diagram is sure to establish new paradigms and win the war. With Six Sigma, everything is possible!

Now I'm even more sure I retired at the right time...

11 Comments:

I can't say I'm too surprised, but then again I am currently embroiled in my NROTC Leadership and Management course...

11/15/2005 8:31 PM

Bubblehead, some of the largest For several years now, major U.S. defense contractors have required six sigma, black belt certification for operations managers and as a qualification criterion for executive selection.

Decisions like this have little relevance in military war fighting and preparedness. There is major relevance for second careers, however. Congress ought to stop the gaming. That will be the day.

11/16/2005 12:32 AM

What the Navy needs to do, is subtract points for anyone who has an MBA. Warfighting is the Navys' business, and the only counting they need to do is beans, bullets, and gas. Points should go to people who do the most towards accomplishing the mission: having the unit prepared to fight, win, and survive war. Everything else is bovine waste material.

Disgusted mode...off

11/16/2005 12:37 AM

Death by buzzword gobbledeegook. This is a classic example of what smart people are spinning their wheels on and not making anything for big navy but PPT and FITREP bullets. I have been involved with the Human Capital Strategy from birth, and it is just as bad WRT lack of clear, directive language. These folks read a book, go to a 1 week offsite and start talking like they know what they are talking about. I actually pulled a SES to the side after listening to her prattle on about HCS and using tons of "B-school" lingo; I basically told her, "I have an MBA, have read "Play to Your Strengths" been with HCS since Disco started briefing last winter, and I couldn't connect half of what you said. The balance of the officers and senior enlisted in the room might as well have been listening to you speak Korean." She basically told me I didn't know what I was talking about.

I've, moved on. Like 90s TQL, it looks like we are going to dig a little deeper.

11/16/2005 3:03 AM

You hit the nail on the head when you said "I'm glad I retired when I did. Between Diversity initiatives ( Who the f**l thinks we need to recruit more women!?!?)

and these better buisness practices.

Naval Aviation was the first to "go over to the dark side" so now the other communities are racing to catch up with them. As I have said before, I'm all for being a prudent steward of the taxpayers money, but the first and foremost job of a URL officer is to train and be ready to give the :

Chinese, Indians, Arabs, Terrorists, and any one else who threatens the US; a beating they will remember for generations.......

11/16/2005 5:42 AM

When I was first commissioned, I thought that we were supposed to learn how to fight and kill the bad guys. Once I got to SOBC and started learning about TQL, I wondered how this fit in to the warfighting part. (Fortunately at SOAC, we talked only of tactics.) Now I completely understand where it fits in: in the manufacturing environment which produces our warfighting equipment. As a Six Sigma Black Belt for a large manufacturing enterprise, I see these principles at work every day, and they do work...in a manufacturing or business environment. Furthermore, there are certain, LIMITED, aspects of Six Sigma, Deming, etc., which could be applicable to warfighting. Note I said LIMITED. Somewhere along the way, our leadership has forgotten that you learn how to fight wars by studying the history and art of warfare, and NOT by studying current business practices and fads. We do not have a culture that views the study of warfare as virtuous, and this is wrong. It needs to start at the top, and it just is not there. I have felt for some time that our admirals are too out of touch with the fleet, with the warfighter, and this appears to be, more and more, because these guys are setting up their retirement job. I had hoped that the GWOT and OIF would purge the upper ranks of the bureaucrats, but I fear that we have even further to go now...

11/16/2005 9:51 AM

I hear ya, oh how I hear ya. I am in a bit of a dilemma, BTW:

--What I'm doing at work is a manufacturing process; it's just cleverly hidden.

--Our practices are grossly inefficient to my view and I want to fix it. In a previous tour I went to visit all the East Coast shipyards including ones not used by Navy. I saw, like BullNav said, that that 6∑ and LEAN manufacturing can work wonders IFF (if and only if) the team can effect such big change and the gobbledygook goes away. (It usually took a near death experience for the company, like an earlier BRAC did for Portsmouth NSY and how they got LEAN and made overhauls faster cheaper.) It sure would be nice to get me some of that "measure what's important and kill off what ain't" stuff.

--I am not a black belt in anything but Power Point.

--I'm a lower level pogue with no power in a basement (think Stapler Guy in "Office Space").

Bad combination, man. Think good thoughts for me.

11/16/2005 8:16 PM

I love that guy! ("And I could see the squirrels, and they were merry"). I'm in an industry now where a statistical approach to manufacturing is required, but for submarining, my thoughts are they could just reduce it to "use common sense and work together" and get rid of all the concomitant claptrap that goes along with these new initiatives.

11/16/2005 11:42 PM

Chap, roger that. While I spend 5% of my time working on projects that could actually make a difference, I spend the other 95% of the time on my Powerpoint Ranger skills explaining to upper management basic engineering. Oh yeah, that's right, I am an engineer...I forget that sometimes. I feel more like a clerk. I ain't in a basement, but it sure feels like it... One more thing: Lean? That will take a cultural change like no other, and it WILL NOT WORK for a combat organization. I think I need to re-read Thunder Below...

11/17/2005 3:57 AM

You guys are kicking the wrong groin. You are blaming the submarine force leaders for executing what they have been directed to execute despite all the feet dragging and resistance that could be mustered. Perhaps you have forgotten that everyone works for someone else. Do you really think that the submarine force is "running to catch up" with bad ideas? If you are a military leader, there is a 100% chance that you are executing at least one policy that you don't agree with.

Counting bullets beans and gas is great, but it isn't going to get your future capabilities funded. To do that you have to work through CFFC and Congress; you can't just take you ball and go home and still meet your fundamental tasking, which is to be a force provider. With respect to real warfighting initiatives, I think the force has done a great job of setting the standard for rolling modernization despite shrinking funds. The gadgets we are deploying with these days are pretty damn gucci. You haven't been in hell until a "solution facilitator" tells you that you could save money and operational readiness by finishing upkeeps on time. I'm not sure it is productive to blame the guys who live in that hell for all the fire. Doing so only proves that you have the startling ability to recognize the problem and are well qualified to be a solution facilitator.

11/09/2008 10:15 PM

Pretty helpful material, much thanks for this article.

8/24/2012 10:44 PM

Post a Comment

<< Home